Forklifts play a vital role in industrial operations by facilitating the movement of heavy materials. However, Forklift tracking particularly in large-scale industries, can be challenging. The Forklift monitoring system designed by getgeo addresses this issue by providing real-time data on the location, usage, as well as condition of each forklift, ensuring efficient management and maintenance.

In this blog, we’ll learn about forklift tracking systems, and their growing need in industries, and understand its features and benefits in detail.

What is a Forklift Tracking System?

Forklift monitoring system track the movement, health, and usage of forklifts in real-time. It gathers information of the forklift’s location, usage frequency, fuel consumption, and maintenance needs. This helps managers to monitor performance, enhancing productivity, and ensuring security.

Why Every Industry Needs Forklift Tracking Systems

In current scenarios, all industries focus on efficiency, safety, and maximizing their resources. Here forklift monitoring plays a crucial role in keeping operations running smoothly, whether it’s moving heavy pallets in or loading goods into the trucks.

Forklifts are the backbone of many construction and manufacturing facilities, but managing a forklift can be challenging. Without a tracking system, industries face several issues such as costly downtime, safety risks, and inefficiencies in fleet utilization.

Additionally, forklift monitoring improves operational efficiency by quickly locating forklifts, saving time spent on searching for them in large worksites.

This tracking system ensures that forklifts are used efficiently, preventing them from sitting idle or being overworked, which can cause unnecessary wear and tear. It also enhances security by monitoring for unauthorized usage or potential theft.

Furthermore, Forklift Tracking also adds a layer of security that allows industries to monitor unauthorized usage or theft through geofencing and real-time alerts.

How Does Forklift Tracking System Using IoT Work?

An IoT-based forklift monitoring system is far more efficient than traditional methods because it offers real-time, detailed tracking of forklift movement and health.

A key component of this system is a beacon, a small device attached to forklifts that continuously sends signals with the location and status of forklifts.

These signals are picked up by gateways which act as receivers placed around the sites. The gateways then send this information to a central system usually in the cloud where it is analyzed and stored.

By applying these complex algorithms, this real-time data allows you to track the forklift’s movement, monitor how much time each forklift spends working and how frequently it’s being used and even get alerts if something goes wrong.

Features of Forklift Tracking System

The key features of our Forklift Tracking System that enhance operational efficiency and maximize forklift usage are outlined below:

Real-time Location Tracking

Forklifts always move around in industries and finding them as quickly can be challenging. With real-time location tracking, you can see where each forklift is at any given moment.

This means no more wasted time searching for forklifts. You can easily track them by using our forklift tracking system, which helps to improve workflow and efficiency.

Usage Monitoring for Optimal Utilization

Usage monitoring helps you to track how much time each forklift spends working and how frequently it’s being used. If you notice a forklift is being used too much, you can schedule maintenance or rotate usage to avoid wear and tear.

Similarly, if a forklift is not being used much, you can decide if it is needed or if it should be used somewhere else. This way, you ensure that all your forklifts are being used effectively, preventing underuse.

Real-Time Operational Status

This feature tracks the forklift’s operations and gives an alert if a forklift is running smoothly or if there are any problems. For instance, if a forklift working slower than usual or if the driver is making too many stops, So in such cases this feature helps you by giving an alert so you can make modifications.

Additionally , you can ensure that your forklift always works in the best condition and help to prevent small issues from turning into bigger ones.

Historical Analysis for Performance and Location Insights

Over time, you will have lots of data about your forklift such as how much they are used, and how frequently they need maintenance. With the help of Historical analysis, you can spot patterns. For instance, forklifts always break down around the same time every year or certain forklifts need repairs more often than others.

With this feature, you can also find if some forklifts are performing better or whether they have a tendency to remain in one spot for long periods which affects efficiency. It also helps you learn from the past to improve future operations.

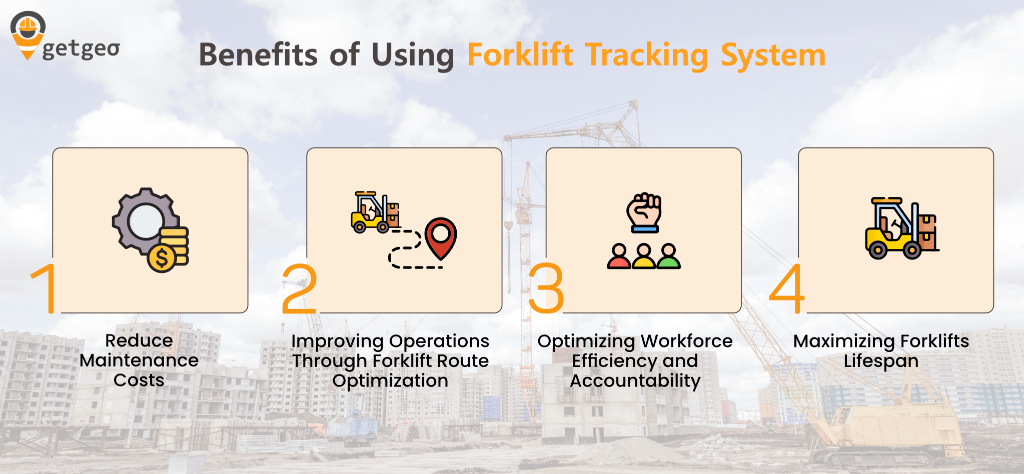

Benefits of Using Forklift Tracking System

The Forklift monitoring System also offers a range of benefits that make maintenance smarter, improve operations, and boost efficiency are explained below:

1. Reduce Maintenance Costs

Forklift tracking systems help to reduce maintenance costs by offering real-time data on usage and condition. With BLE tags and beacons, these systems allow for preventive maintenance by tracking forklift performance and predicting when maintenance is needed.

Additionally, forklift monitoring leads to cost savings through reduced fuel consumption by optimizing routes and minimized downtime by identifying issues early. Furthermore, it helps with better equipment utilization and ensures forklifts are used efficiently, reducing unnecessary expenses.

2. Improving Operations Through Forklift Route Optimization

The system helps in forklift route optimization by providing location tracking using beacons. It can spot locations with high traffic or delays where forklifts might be wasting time.

Moreover, the system makes sure that forklifts travel the fastest routes by modifying the routes, which reduces delays and boosts operational effectiveness. This route optimization allows forklifts to complete more tasks in less time, improving overall productivity.

3. Optimizing Workforce Efficiency and Accountability

The system monitors how well operators use forklifts by tracking tasks like how many pallets they move or the distance travelled. This information helps managers to see how efficient operators are and spot areas where they can improve and set performance targets.

Managers can also use real-time tracking to make sure operators are using forklifts safely.

4. Maximizing Forklifts Lifespan

One of the key advantages of utilizing a forklift tracking system is increasing the life of forklifts. By continuously monitoring the performance and usage patterns of each forklift, managers can identify potential issues before they become serious problems.

The system ensures that forklifts operate at optimal levels which leads to fewer breakdowns, extends the life of equipment.

Use Cases for Forklift Monitoring Technology

Here are some key use cases for forklift tracking System:

Find Forklifts Faster, Anytime:

With real-time path tracking, you can easily locate your forklifts whenever you need them.

Reduce Energy Waste, Boost Savings:

By optimizing routes and reducing idle time the forklift system saves energy, reduces costs, and makes operations more efficient.

Monitor Forklift Movements and Task Progress:

Real-time tracking of forklift locations allows you to monitor work progress and make changes that are needed.

Improve Fleet Utilization:

With detailed usage data, you can also optimize fleet management by understanding which forklifts are underused or overused which ensures efficient deployment and reduces downtime.

Conclusion

Overall, forklift tracking systems using IoT are essential for modern industries that provide real-time insights into forklift locations, usage and performance. They also help to optimize fleet management, reduce downtime, lower maintenance costs, and improve safety.

At getgeo, we are specialize in creating Manpower and Equipment Tracking Solutions. Let’s work together to turn your goals into concrete results.

Frequently Asked Questions

What is forklift tracking?

A forklift tracking system utilizes BLE tags, beacons, and a location engine to monitor forklift movement, usage, and health in real-time.

What are the main benefits of using forklift tracking systems?

The benefit of using forklift tracking systems offer real-time tracking, route optimization, lower maintenance cost and improved workforce accountability which leads to smoother operations and higher productivity.

Does forklift monitoring system help with maintenance?

Yes, forklift tracking helps in maintenance by monitoring real-time usage, detecting issues early, and enabling preventive maintenance.

What technologies are used in forklift tracking?

Forklift tracking uses IoT technology, including beacons attached to forklifts, gateways to receive signals, and cloud-based systems to analyze and store data.

Are forklift tracking systems customizable?

Yes, Forklift tracking systems can be easily customized to meet the specific needs of any industry.